When the copper casting appears shrinkage, shrinkage phenomenon, in fact, it is because its own pouring temperature is relatively high or low, the next word, it is because its own casting speed is relatively fast or too slow caused; The shrinkage and shrinkage of the copper casting, that is, because the design of the pouring system is not suitable, as well as the shortage of the feeding effect of the riser, the cold iron position is not conducive to the solidification of the sequence.

In this respect, we should pay attention to adjusting its pouring temperature and pouring speed, and then, we should pay attention to improving its pouring system design, in this respect, in fact, it will facilitate us to carry out sequential solidification and increase its riser feeding capacity. It is reasonable to set up a dark riser or use a cold core to prevent overheating of individual parts of its metal type.

In the face of the bottom casting phenomenon of copper casting, we actually need to pay attention to its pouring speed can not be too slow, and when the top casting, do not be too fast, in this respect, in fact, it is to prevent the phenomenon of local overheating.

For the insufficient pouring (lack of meat) defects of copper casting, to a large extent, it is because the impurity content is relatively high, and the fluidity itself is relatively low, and then, because the pouring temperature is too low, or because the pouring speed is too slow or the phenomenon of mold leakage will lead to the production of insufficient pouring (lack of meat) defects.

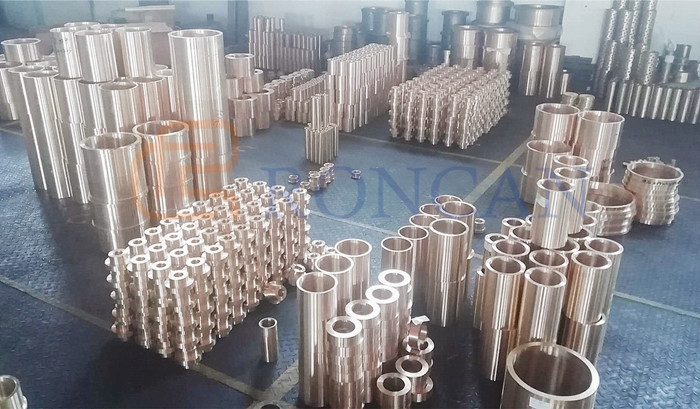

Jiaxing Rongchang Bearing is a professional production of plain bearings company, is approved by the relevant state departments registered enterprises. Main products: copper sleeve, copper bearing, copper slide, copper slider, copper worm gear, sliding bearing seat and other copper products. Our company adopts the advanced production process ---- centrifugal casting, the copper sleeve and copper bearing shell produced can significantly improve the tightness and wear resistance of the castings compared with sand casting, and have good tensile strength, flexural strength and tensile ratio. The material of copper sleeve is brass, tin bronze, aluminum bronze, etc. The company adheres to the principle of "integrity first, customer first", and has established long-term friendly cooperative relations with many enterprises. Warmly welcome friends from all walks of life to visit, study and negotiate business, hotline: 0573-84609502!!